Hy90 Semi automatic Series

Centrifugal purifier Machine

Effectively separate fine particles of metal impurities from oil products or industrial fluids to keep oil products clean all the time

Featured Products

No filter element

Hy90 Centrifugal purifier does not need filter element, The filter element not only needs to replace the filter element frequently, but also is easy to be blocked

Bypass operation

Offline and online by-pass without occupying space. It can be used by connecting the oil pipe without changing the original oil supply equipment

Lightweight and portable

It elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Regular slag cleaning

Regularly manually remove the residue / sludge separated from the oil in the rotor.

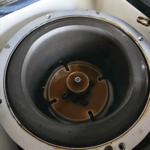

Principle of Operation

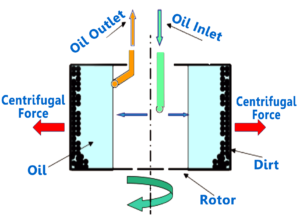

Oil is pumped into the centrifuge and directed into the rotor of the centrifuge. The centrifugal rotor is connected to the motor drive directly. The motor drives the rotor spinning and the rotor rotates quickly. The centrifugal force in the rotor causes the dirt particles present accelerate radially and deposit on the internal wall of the rotor. In the course of operation these deposits form a thick cake.

Centrifugal force is capable of removing a wide range of particles extending into sub-micron range. The removal of particles by centrifugal force is based on their relative density; therefore there is no restriction on contaminant size.

A barrier filtration device removes particles from oil based on filter element. Hongyi centrifugal oil cleaner is not a barrier filtration device; it has no filter element and no need filtration media to remove contaminant particles.

The Benefits

- Improved purity of the oil

- Extended oil life change period

- Increased engine/machinery Life

- Reduces engine/machinery wear

- Reduces maintenance costs

- Cuts waste disposal costs

- Reduces application downtime

- Maximized in-service time for machinery

- Very short investment recovery period & fast return on investment

- No replacement element & recurring cost

- Reduced contamination in oil

- Less load on oil filters & heat exchangers

- Less maintenance of filters & heat exchangers – operational / cost benefit

- Less wear of quench oil transfer pumps – operational & cost saving

- Less furnace downtime

- Increased production

- Reduces total cost of ownersh

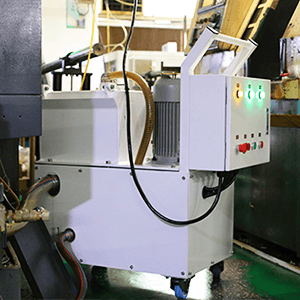

hy90A

Technical Parameters Of Hy90A Centrifugal Oil Cleaner:

Operating Principle:Centrifugal Separation

Rotor Dirt Holding Capacity:4.5L

Optimal Flow Volume:16L/min

Centrifugal Force:1821G

Total power:2.75Kw

Outlet pipe diameter:DN40mm

Pressure range:0.4-0.6Mpa

Control mode:manual operation

SIZE:900*480*1000mm

Slag discharge mode:manual operation

Max. Flow Volume:30L/min

Rotor Speed:3500rpm

Voltage:380V/50~60Hz

Inlet pipe diameter:DN25mm

Exit height:400mm

control panel:push-button

working temperature:0~80℃

Weight:180Kg

hy90B

Technical Parameters Of Hy90B Centrifugal Oil Cleaner:

Operating Principle:Centrifugal Separation

Rotor Dirt Holding Capacity:4.5L

Optimal Flow Volume:16L/min

Centrifugal Force:1821G

Total power:2.75Kw

Outlet pipe diameter:DN40mm

Pressure range:0.4-0.6Mpa

Control mode:manual operation

SIZE:1100*720*1500mm

Slag discharge mode:manual operation

Max. Flow Volume:30L/min

Rotor Speed:3500rpm

Voltage:380V/50~60Hz

Inlet pipe diameter:DN25mm

Exit height:900mm

control panel:push-button

working temperature:0~80℃

Weight:200Kg

Application Cases

Hongyi centrifugal oil cleaner is very suitable to clean aluminium / copper / S.S. wire drawing, quenching oil; forging, reaming, turbine oil; heat treatment, fastener manufacturing, furnace oil; gear oil; transmission oil; thermic fluid, neat cutting oil; bright bar manufacturing, cement, thermal, steel plants anti rust, stamping oil; transmission oil; grinding machine, honing machine, compressor oil; straight cutting oil; test bed oils; water glycol based cutting oils; hydraulic oil and so on.